The department operates a ‘sensitive sites’ service to identify locations of sensitive commercial production systems across Western Australia's agricultural region.

Sensitive commercial production sites may include certified organic or certified biodynamic enterprises, as well as managed commercial tree nurseries, licenced aquaculture, and commercial viticulture businesses.

The service exists to facilitate contact between sensitive enterprises and nearby landholders so they can work together to plan for and mitigate any risks from activities conducted near sensitive sites.

Locations are shown in an online Sensitive Sites map (see below). Landholders may register annually to have their premises included in the map, which is updated each year.

While the Sensitive Sites map provides information for producers, registration as a sensitive production site does not provide any legal protection.

Application process

Applications for inclusion in the sensitive sites map must be assessed by DPIRD, which reserves the right to ask any applicant for documentary evidence and to decline any application which fails to meet the guidelines.

DPIRD will contact current Sensitive Site registrants before the annual map is produced to remind them to register when the auunal registrations open.

If you believe that you have a sensitive production system listed as above, please apply during the registration period.

Sensitive Sites map

Disclaimer

I understand and agree with the Department of Primary Industry and Regional Development Western Australia (DPIRD), which expression includes the State of Western Australia and its servants and agents that:

- The locations of these sites in the Map and description of them as sensitive sites are based on information and requests provided to DPIRD by growers in DPIRD's database. DPIRD is not able to verify or identify the nature or extent of sensitivity of mapped sites, types of activities that may pose risks to the sites, or the extent of those risks. Nor can DPIRD advise whether there are other sites that may be sensitive, but are not shown on the map because they or their sensitivity are unknown to DPIRD or their owners did not request listing of them

- Mapped data and other information in this package may not be accurate, current or complete due to changes which may not be notified to DPIRD or may not be immediately updated in this package

- I should not make significant decisions in reliance on information obtained from this package, but should make my own investigations, consult relevant property owners and obtain updated professional advice relevant to my circumstances

- I accept all risks and responsibility for losses, damages, costs and other consequences resulting directly or indirectly from using this site or information or material in it

- To the maximum extent permitted by law, DPIRD excludes all liability, in negligence and otherwise, to me or anyone else, resulting directly or indirectly from me using this site or information or material in it. I release DPIRD from all such liability.

Coexistence of different production systems

Different production systems, including Certified organic, certified biodynamic, non-GM and GM production systems, co-exist in Western Australia.

Western Australian growers have the choice to use a wide range of production systems to generate products that meet their customer specifications. To support coexistence, growers need to consider their system and implement risk management strategies to minimise any potential negative impacts to other growers.

Certified organic, certified biodynamic, non-GM and GM production systems all have specific requirements as outlined in Table 1. To assist in managing various systems that may be within close proximity, growers should discuss individual production system requirements with their neighbours.

The proforma letter (see: Coexistence letter) can be used to help you initiate a discussion with your neighbours

In agricultural production systems, animal, plant and soil material can move from one property to another via a number of mechanisms. Similarly, agricultural inputs such as fertilisers and pesticides can affect non-intended targets.

Table 1 Summary of the main production system requirements for certified organic (or biodynamic), non-GM and GM production systems

|

Requirement |

Certified Organic |

Non-GM |

GM |

|

Accredited production system |

Standards and certification requirements* |

None required |

Accreditation training |

|

Notification requirements |

|

|

|

|

Neighbours |

Yes |

None required |

Recommended |

|

Statutory authorities |

Yes |

None required |

Recommended |

|

Property and farm system requirements |

|

|

Must comply with, and document compliance with licence conditions |

|

Pesticides |

Only permitted substances |

No specific exclusions |

No specific exclusions |

|

Fertilisers |

Only permitted inputs |

No specific exclusions |

No specific exclusions |

|

GM material |

Not permitted |

No specific exclusions |

No specific exclusions |

|

Market threshold(s) in produce |

|

|

|

|

Pesticides |

Yes (check certifier standards) |

Yes (industry standard) |

Yes (industry standard) |

|

GM material |

Not permitted in product or on farm |

Must contain less than industry threshold for GM presence (0.9%) |

No specific exclusions |

|

Consequence of exceeding market threshold |

|

Loss of non-GM market |

Loss of market |

* Individual organic/biodynamic certifiers in Australia may have slightly different requirements

While it is possible to have processes in place to minimise incidents of material transfer t is not possible to eliminate them.

Growers need to plan to minimise the possibility of impacting neighbours.

Discuss your planned production activities with your neighbours. You may find it helpful to fill in the proforma 'Coexistence letter' and give it to your neighbour to start a discussion.

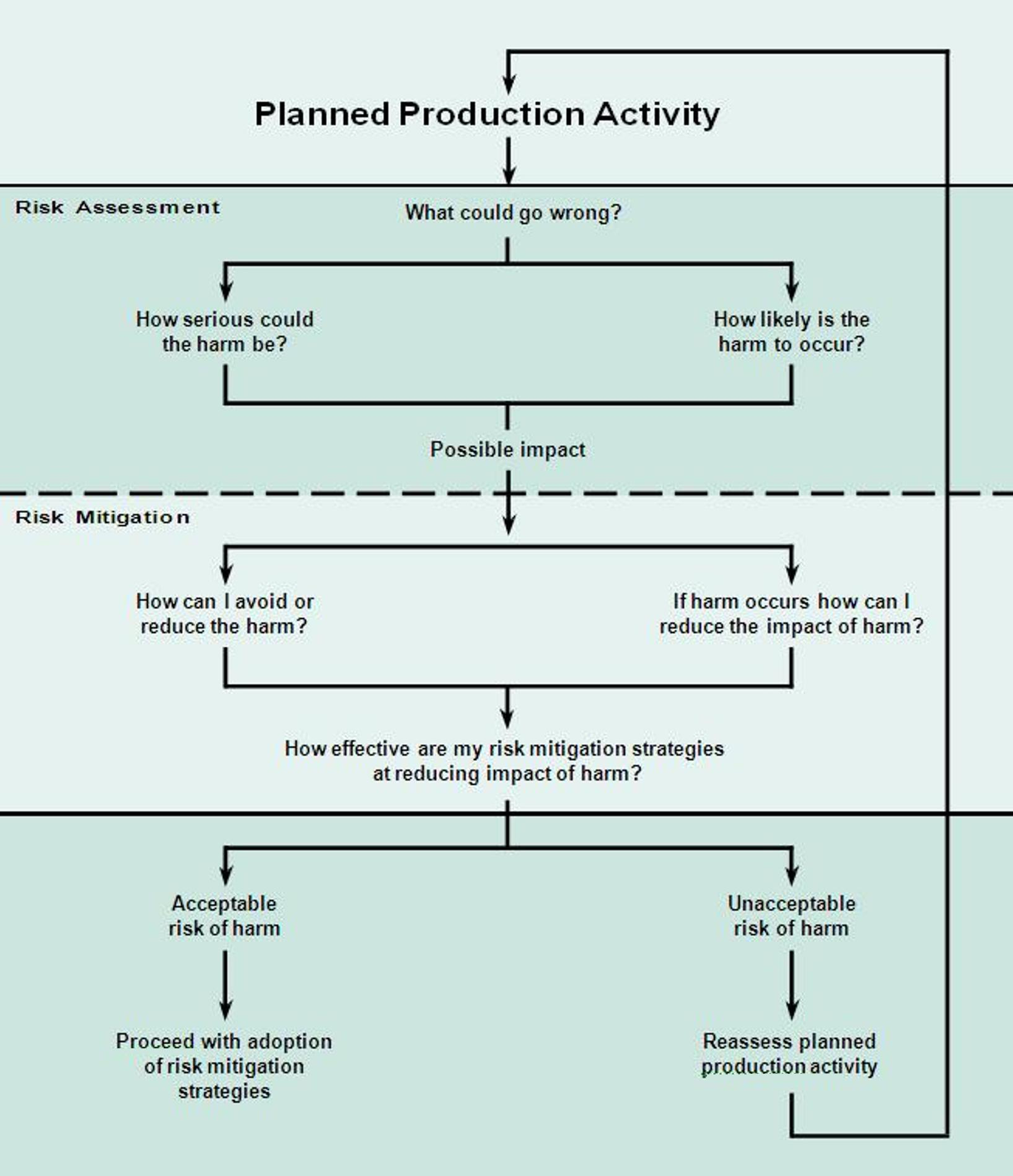

Figure 1 shows some of the matters to consider during risk assessment.

Growers have a duty of care to manage their crops to minimise impacts on others. Overall, you need to make an informed judgement on whether the risk of harm of your production activity to your neighbour’s production system is manageable.

If the risk is not manageable you might re-consider your proposed production activity.

As everyone’s circumstances differ it is not possible to provide specific risk management guidance. Instead, consider factors which may influence the risk of material (for example, soil, plants, pesticides, disease inoculum and so on) transferring from your property to other properties and possible steps you might adopt to minimise these risks (Table 2).

Table 2 Factors influencing the risk of material transfer between properties**

|

Factors |

Influence |

Practices which may decrease risk of material transfer between properties |

|

Proximity |

Distance between location of your production system and the location of any sensitive sites |

'Best practice' such as buffer zones between GM and non-GM, organic and non-organic properties for example could be considered. |

|

Mode of transfer |

|

|

|

Wind |

Consider prevailing winds (strength and direction) |

|

|

Water |

Consider possible modes of water borne transfer |

|

|

Physical movement |

Consider possible person, animal, vehicle based, soil borne, admixture (i.e. grain movement) transfer |

|

** Note that other influences may exist that suggest risk which have not been covered in this table

Further information about chemical requirements is available at:

Contact us

-

Sensitive Sites Information Service